ADVANCED PLANNING AND SCHEDULING

Plan your tasks more easily and quickly with Dinamo APS+.

Plan your tasks more easily and quickly with Dinamo APS+.

What is APS?

Advanced Planning and Scheduling (APS) stands as a pivotal digital solution, facilitating the meticulous planning and management of production operations within the confines of resource limitations.

In achieving the balance of supply and demand, it is a critical component of supply chain planning. Integrated with other essential components such as ERP and MES software, it plays a significant role in companies' steps towards digitalization.

What are the benefits of APS for businesses?

Advanced Planning and Scheduling (APS) software reduces order delays, thereby increasing customer satisfaction. Simultaneously, it ensures the accurate utilization of company capacity. It decreases waste, including stock levels and capacity wastage.

By comparing performance indicators (KPIs) with scenarios created under different conditions, it provides the opportunity to achieve the best scheduling that meets the needs.

What are the advantages of DinamoAPS+?

Thanks to its flexibility, it adapts to the needs of different sectors. It can be quickly and seamlessly integrated with ERP and MES programs. It is entirely native, thus offering its functionality to businesses with the best cost-benefit ratios.

It prepares schedules that provide flexible and dynamic solutions in response to disruptions in the production field. It enhances the accuracy of delivery date commitments, minimizes setup times, and ensures efficient capacity utilization.

How does DinamoAPS+ benefit your business?

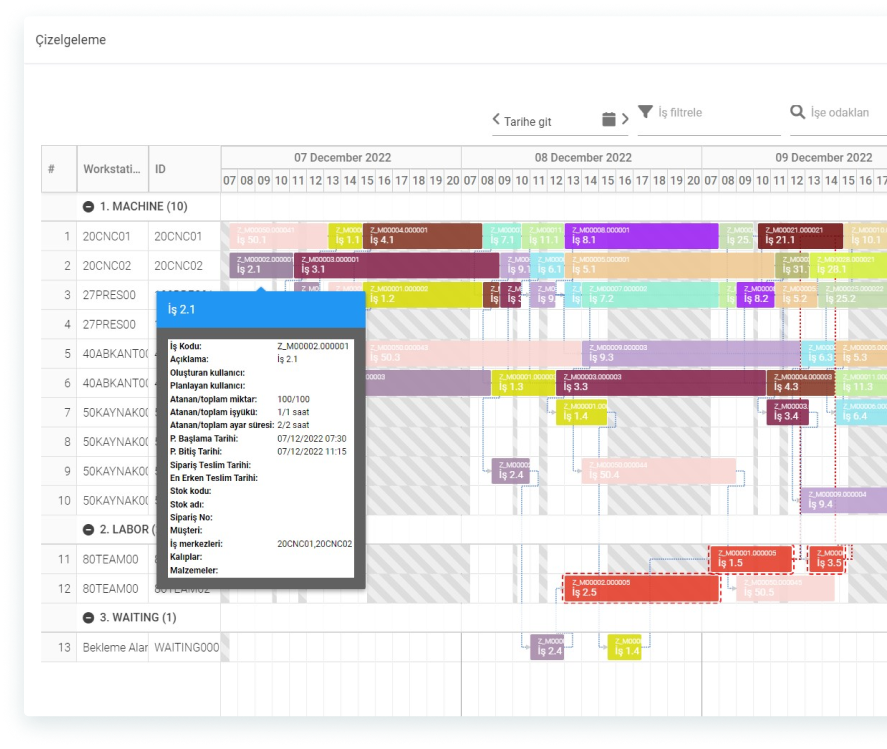

DinamoAPS+ rapidly prioritizes tasks, minimizing setup times in resources and reducing the number of jobs in the queue through efficient utilization of production resources. It enhances production speed with the 'transfer batch size' and addresses deviations in tasks through the 'rescheduling' feature. It provides the ability to set delivery dates with 'Constraint Work Center Fixing.' By planning jobs with the Theory of Constraints approach, it performs forward scheduling from the bottleneck to the delivery date and backward scheduling from the resources before the bottleneck, reducing Work-in-Process (WIP) stocks. DinamoAPS+ dynamically calculates capacity, taking into account factors such as Resources, Alternative Resources, Setup Code Transition Matrices, Job and Resource Linkage/Constraint Definitions, Coloring Rules, HR Integration, Machine Maintenance Integration, Facility Definitions, and Shift definitions. It can be easily integrated into ERP programs and MES applications, enabling effective, economical, flexible, and efficient planning.

Let Us Call You

For more detailed information and all your questions, please contact us, and we'll give you a call.